Different Types of Insulation that contribute in Energy Efficiency of the Building

[icegram campaigns="18680"]

When insulating your home, you can choose from many types of insulation. To choose the best type of insulation, you should first determine the following:

- Where you want or need to install/add insulation

- The recommended R-values for areas you want to insulate.

Installing Insulation

The maximum thermal performance or R-value of insulation is very dependent on proper installation. Homeowners can install some types of insulation — notably blankets and materials that can be poured in place. (Liquid foam insulation materials can be poured, but they require professional installation). Other types require professional installation.

When hiring a professional certified installer:

- Obtain written cost estimates from several contractors for the R-value you need, and don’t be surprised if quoted prices for a given R-value installation vary by more than a factor of two.

- Ask contractors about their air-sealing services and costs as well, because it’s a good idea to seal air leaks before installing insulation.

To evaluate blanket installation, you can measure batt thickness and check for gaps between batts as well as between batts and framing. In addition, inspect insulation for a tight fit around building components that penetrate the insulation, such as electrical boxes. To evaluate sprayed or blown-in types of insulation, measure the depth of the insulation and check for gaps in coverage.

If you choose to install the insulation yourself, follow the manufacturer’s instructions and safety precautions carefully and check local building and fire codes. Do-it-yourself instructions are available from the fiberglass and mineral wool trade group. The cellulose trade group recommends hiring a professional, but if there isn’t a qualified installer in your area or you feel comfortable taking on the job, you may be able to find guidance from manufacturers.

The table below provides an overview of most available insulation materials, how they are installed, where they’re typically installed, and their advantages.

Types of Insulation

| TYPE | MATERIAL | WHERE APPLICABLE | INSTALLATION METHODS | ADVANTAGES |

|---|---|---|---|---|

| Blanket: batts and rolls | FiberglassMineral (rock or slag) woolPlastic fibersNatural fibers | Unfinished walls, including foundation wallsFloors and ceilings | Fitted between studs, joists, and beams. | Do-it-yourself.Suited for standard stud and joist spacing that is relatively free from obstructions. Relatively inexpensive. |

| Concrete block insulationand insulating concrete blocks | Foam board, to be placed on outside of wall (usually new construction) or inside of wall (existing homes):Some manufacturers incorporate foam beads or air into the concrete mix to increase R-values | Unfinished walls, including foundation wallsNew construction or major renovationsWalls (insulating concrete blocks) | Require specialized skillsInsulating concrete blocks are sometimes stacked without mortar (dry-stacked) and surface bonded. | Insulating cores increases wall R-value.Insulating outside of concrete block wall places mass inside conditioned space, which can moderate indoor temperatures.Autoclaved aerated concrete and autoclaved cellular concrete masonry units have 10 times the insulating value of conventional concrete. |

| Foam board or rigid foam | PolystyrenePolyisocyanuratePolyurethane | Unfinished walls, including foundation wallsFloors and ceilingsUnvented low-slope roofs | Interior applications: must be covered with 1/2-inch gypsum board or other building-code approved material for fire safety.Exterior applications: must be covered with weatherproof facing. | High insulating value for relatively little thickness.Can block thermal short circuits when installed continuously over frames or joists. |

| Insulating concrete forms (ICFs) | Foam boards or foam blocks | Unfinished walls, including foundation walls for new construction | Installed as part of the building structure. | Insulation is literally built into the home’s walls, creating high thermal resistance. |

| Loose-fill and blown-in | CelluloseFiberglassMineral (rock or slag) wool | Enclosed existing wall or open new wall cavitiesUnfinished attic floorsOther hard-to-reach places | Blown into place using special equipment, sometimes poured in. | Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions. |

| Reflective system | Foil-faced kraft paper, plastic film, polyethylene bubbles, or cardboard | Unfinished walls, ceilings, and floors | Foils, films, or papers fitted between wood-frame studs, joists, rafters, and beams. | Do-it-yourself.Suitable for framing at standard spacing.Bubble-form suitable if framing is irregular or if obstructions are present.Most effective at preventing downward heat flow, effectiveness depends on spacing. |

| Rigid fibrous or fiber insulation | FiberglassMineral (rock or slag) wool | Ducts in unconditioned spacesOther places requiring insulation that can withstand high temperatures | HVAC contractors fabricate the insulation into ducts either at their shops or at the job sites. | Can withstand high temperatures. |

| Sprayed foam and foamed-in-place | CementitiousPhenolicPolyisocyanuratePolyurethane | Enclosed existing wallOpen new wall cavitiesUnfinished attic floors | Applied using small spray containers or in larger quantities as a pressure sprayed (foamed-in-place) product. | Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions. |

| Structural insulated panels (SIPs) | Foam board or liquid foam insulation coreStraw core insulation | Unfinished walls, ceilings, floors, and roofs for new construction | Construction workers fit SIPs together to form walls and roof of a house. | SIP-built houses provide superior and uniform insulation compared to more traditional construction methods; they also take less time to build. |

Blanket: Batt and Roll Insulation

Blanket insulation — the most common and widely available type of insulation — comes in the form of batts or rolls. It consists of flexible fibers, most commonly fiberglass. You also can find batts and rolls made from mineral (rock and slag) wool, plastic fibers, and natural fibers, such as cotton and sheep’s wool. Learn more about these insulation materials.

Batts and rolls are available in widths suited to standard spacing of wall studs, attic trusses or rafters, and floor joists: 2 inch x 4 inch walls can hold R-13 or R-15 batts; 2 inch x 6 inch walls can use R-19 or R-21 products. Continuous rolls can be hand-cut and trimmed to fit. They are available with or without facings. Manufacturers often attach a facing (such as kraft paper, foil-kraft paper, or vinyl) to act as a vapor barrier and/or air barrier. Batts with a special flame-resistant facing are available in various widths for basement walls and other places where the insulation will be left exposed. A facing also helps facilitate fastening during installation.

See the table below for an overview of standard and high-performance (medium-density and high-density) fiberglass blankets and batts characteristics.

Fiberglass Batt Insulation Characteristics

This table is for comparison of fiberglass batts only. Determine actual thickness, R-value, and cost from manufacturer and/or local building supplier.

| THICKNESS (INCHES) | R-VALUE | COST (CENTS/SQ. FT.) |

|---|---|---|

| 3 1/2 | 11 | 12-16 |

| 3 5/8 | 13 | 15-20 |

| 3 1/2 (high density) | 15 | 34-40 |

| 6 to 6 1/4 | 19 | 27-34 |

| 5 1/4 (high density) | 21 | 33-39 |

| 8 to 8 1/2 | 25 | 37-45 |

| 8 (high density) | 30 | 45-49 |

| 9 1/2 (standard) | 30 | 39-43 |

| 12 | 38 | 55-60 |

Concrete Block Insulation

Concrete blocks are used to build home foundations and walls, and there are several ways to insulate them. If the cores aren’t filled with steel and concrete for structural reasons, they can be filled with insulation, which raises the average wall R-value. Field studies and computer simulations have shown, however, that core filling of any type offers little fuel savings, because heat is readily conducted through the solid parts of the walls such as block webs and mortar joints.

It is more effective to install insulation over the surface of the blocks either on the exterior or interior of the foundation walls. Placing insulation on the exterior has the added advantage of containing the thermal mass of the blocks within the conditioned space, which can moderate indoor temperatures.

Some manufacturers incorporate polystyrene beads into concrete blocks, while others make concrete blocks that accommodate rigid foam inserts.

In the United States, two varieties of solid, precast autoclaved concrete masonry units are now available: autoclaved aerated concrete (AAC) and autoclaved cellular concrete (ACC). This material contains about 80% air by volume and has been commonly used in Europe since the late 1940s. Autoclaved concrete has ten times the insulating value of conventional concrete. The blocks are large, light, and easily sawed, nailed, and shaped with ordinary tools. The material absorbs water readily, so it requires protection from moisture. Precast ACC uses fly ash instead of high-silica sand, which distinguishes it from AAC. Fly ash is a waste ash produced from burning coal in electric power plants.

Hollow-core units made with a mix of concrete and wood chips are also available. They are installed by stacking the units without using mortar (dry-stacking) and filling the cores with concrete and structural steel. One potential problem with this type of unit is that the wood is subject to the effects of moisture and insects.

Concrete block walls are typically insulated or built with insulating concrete blocks during new home construction or major renovations. Block walls in existing homes can be insulated from the inside. Go to insulation materials for more information about the products commonly used to insulate concrete block.

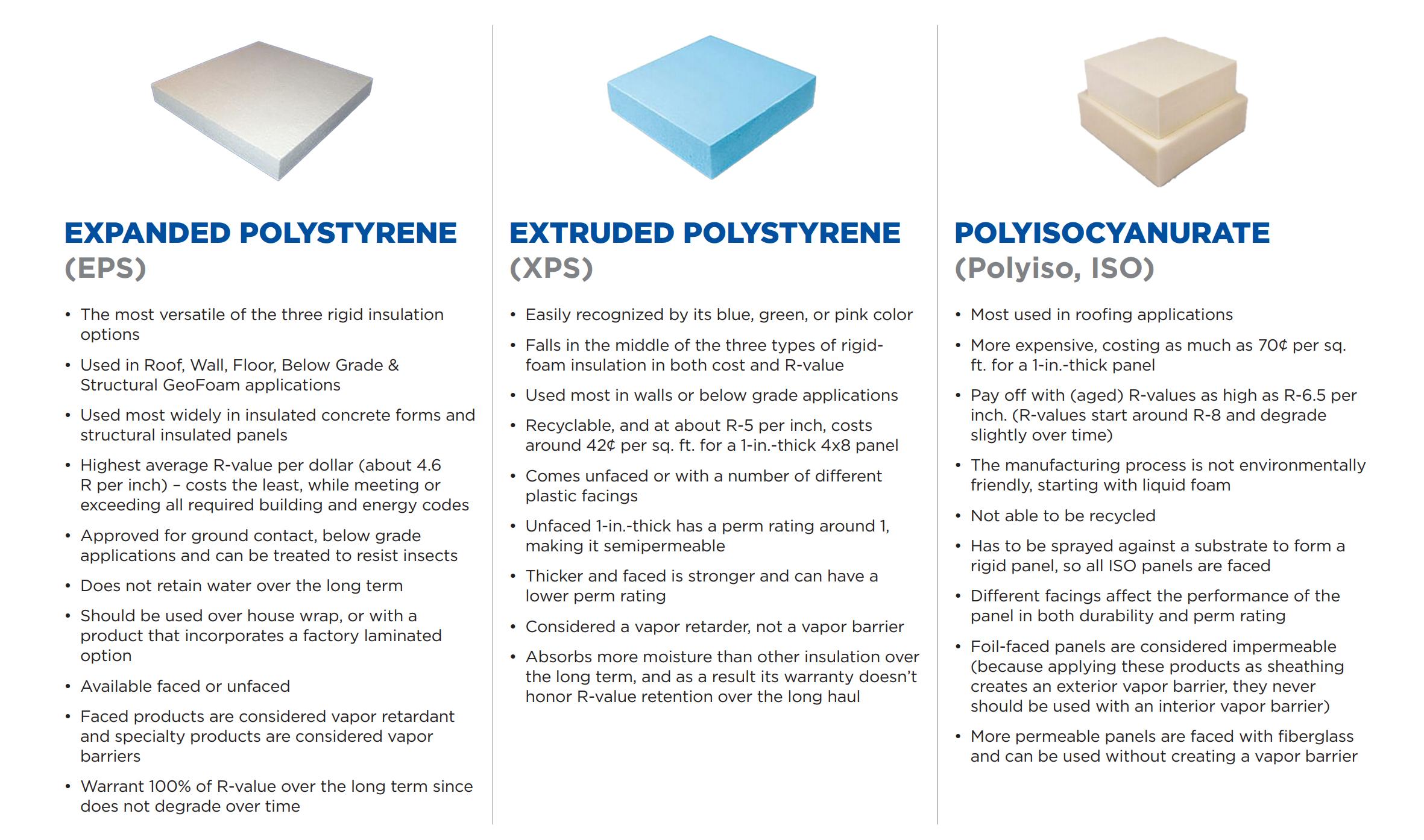

Foam Board or Rigid Foam

Foam boards — rigid panels of insulation — can be used to insulate almost any part of your home, from the roof down to the foundation. They are very effective in exterior wall sheathing, interior sheathing for basement walls, and special applications such as attic hatches. They provide good thermal resistance (up to 2 times greater than most other insulating materials of the same thickness), and reduce heat conduction through structural elements, like wood and steel studs. The most common types of materials used in making foam board include polystyrene, polyisocyanurate (polyiso), and polyurethane.

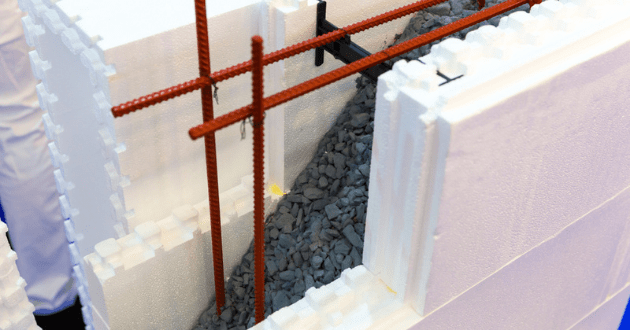

Insulating Concrete Forms

Insulating concrete forms (ICFs) are basically forms for poured concrete walls, which remain as part of the wall assembly. This system creates walls with a high thermal resistance, typically about R-20. Even though ICF homes are constructed using concrete, they look like traditional stick-built homes.

ICF systems consist of interconnected foam boards or interlocking, hollow-core foam insulation blocks. Foam boards are fastened together using plastic ties. Along with the foam boards, steel rods (rebar) can be added for reinforcement before the concrete is poured. When using foam blocks, steel rods are often used inside the hollow cores to strengthen the walls.

The foam webbing around the concrete-filled cores of blocks can provide easy access for insects and groundwater. To help prevent these problems, some manufacturers make insecticide-treated foam blocks and promote methods for waterproofing them. Installing an ICF system requires an experienced contractor, available through the Insulating Concrete Form Association.

Loose-Fill and Blown-In Insulation

Loose-fill insulation consists of small particles of fiber, foam, or other materials. These small particles form an insulation material that can conform to any space without disturbing structures or finishes. This ability to conform makes loose-fill insulation well suited for retrofits and locations where it would be difficult to install other types of insulation.

The most common types of materials used for loose-fill insulation include cellulose, fiberglass, and mineral (rock or slag) wool. All of these materials are produced using recycled waste materials. Cellulose is primarily made from recycled newsprint. Most fiberglass products contain 40% to 60% recycled glass. Mineral wool is usually produced from 75% post-industrial recycled content. The table below compares these three materials.

Recommended Specifications by Loose-Fill Insulation Material

| CELLULOSE | FIBERGLASS | ROCK WOOL | |

|---|---|---|---|

| Density in lb/ft3 (kg/m3) | 1.5–2.0 (24–36) | 0.5–1.0 (10–14) | 1.7 (27) |

| Weight at R-38 in lb/ft2 (kg/m2) | 1.25–2.0 (6–10) | 0.5–1.2 (3–6) | 1.6–1.8 (8–9) |

For Attic Applications

| CELLULOSE | FIBERGLASS | ROCK WOOL | |

|---|---|---|---|

| OK for 1/2″ drywall, 24″ on center? | No | Yes | No |

| OK for 1/2″ drywall, 16″ on center? | Yes | Yes | Yes |

| OK for 5/8″ drywall, 24″ on center? | Yes | Yes | Yes |

Some less common loose-fill insulation materials include polystyrene beads and vermiculite and perlite. Loose-fill insulation can be installed in either enclosed cavities such as walls, or unenclosed spaces such as attics. Cellulose, fiberglass, and rock wool are typically blown in by experienced installers skilled at achieving the correct density and R-values. Polystyrene beads, vermiculite, and perlite are typically poured.

The Federal Trade Commission has issued the “Trade Regulation Rule Concerning the Labeling and Advertising of Home Insulation” (16 CFR Part 460). The Commission issued the R-value Rule to prohibit, on an industry-wide basis, specific unfair or deceptive acts or practices. The Rule requires that manufacturers and others who sell home insulation determine and disclose each products’ R-value and related information (e.g., thickness, coverage area per package) on package labels and manufacturers’ fact sheets. R-value ratings vary among different types and forms of home insulations and among products of the same type and form.

. For loose-fill insulation, each manufacturer must determine the R-value of its product at settled density and create coverage charts showing the minimum settled thickness, minimum weight per square foot, and coverage area per bag for various total R-values.

This is because as the installed thickness of loose-fill insulation increases, its settled density also increases due to compression of the insulation under its own weight. Thus, the R-value of loose-fill insulation does not change proportionately with thickness. The manufacturers’ coverage charts specify the bags of insulation needed per square foot of coverage area; the maximum coverage area for one bag of insulation; the minimum weight per square foot of the installed insulation; and the initial and settled thickness of the installed insulation needed to achieve a particular R-value.

Radiant Barriers and Reflective Insulation Systems

Unlike most common insulation systems, which resist conductive and sometimes convective heat flow, radiant barriers and reflective insulation work by reflecting radiant heat. Radiant barriers are installed in homes — usually in attics — primarily to reduce summer heat gain, which helps lower cooling costs. Reflective insulation incorporates radiant barriers — typically highly reflective aluminum foils — into insulation systems that can include a variety of backings, such as kraft paper, plastic film, polyethylene bubbles, or cardboard, as well as thermal insulation materials.

Radiant heat travels in a straight line away from any surface and heats anything solid that absorbs its energy. When the sun heats a roof, it’s primarily the sun’s radiant energy that makes the roof hot. A large portion of this heat travels by conduction through the roofing materials to the attic side of the roof. The hot roof material then radiates its gained heat energy onto the cooler attic surfaces, including the air ducts and the attic floor. A radiant barrier reduces the radiant heat transfer from the underside of the roof to the other surfaces in the attic. To be effective, it must face an air space.

Radiant barriers are more effective in hot climates, especially when cooling air ducts are located in the attic. Some studies show that radiant barriers can lower cooling costs 5% to 10% when used in a warm, sunny climate. The reduced heat gain may even allow for a smaller air conditioning system. In cool climates, however, it’s usually more cost-effective to install more thermal insulation.

Rigid Fiber Board Insulation

Rigid fiber or fibrous board insulation consists of either fiberglass or mineral wool material and is primarily used for insulating air ducts in homes. It is also used when there’s a need for insulation that can withstand high temperatures. These products come in a range of thicknesses from 1 inch to 2.5 inches.

Installation in air ducts is usually done by HVAC contractors, who fabricate the insulation at their shops or at job sites. On exterior duct surfaces, they can install the insulation by impaling it on weld pins and securing with speed clips or washers. They can also use special weld pins with integral-cupped head washers. Unfaced boards can then be finished with reinforced insulating cement, canvas, or weatherproof mastic. Faced boards can be installed in the same way, and the joints between boards sealed with pressure-sensitive tape or glass fabric and mastic.

Sprayed-Foam and Foamed-In-Place Insulation

Liquid foam insulation materials can be sprayed, foamed-in-place, injected, or poured. Foam-in-place insulation can be blown into walls, on attic surfaces, or under floors to insulate and reduce air leakage. Some installations can yield a higher R-value than traditional batt insulation for the same thickness, and can fill even the smallest cavities, creating an effective air barrier. You can use the small pressurized cans of foam-in-place insulation to reduce air leakage in holes and cracks, such as window and door frames, and electrical and plumbing penetrations.

Types of Foam Insulation

Today, most foam materials use foaming agents that don’t use chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs), which are harmful to the earth’s ozone layer.

There are two types of foam-in-place insulation: closed-cell and open-cell. Both are typically made with polyurethane. With closed-cell foam, the high-density cells are closed and filled with a gas that helps the foam expand to fill the spaces around it. Open-cell foam cells are not as dense and are filled with air, which gives the insulation a spongy texture.

The type of insulation you should choose depends on how you will use it and on your budget. While closed-cell foam has a greater R-value and provides stronger resistance against moisture and air leakage, the material is also much denser and is more expensive to install. Open-cell foam is lighter and less expensive but should not be used below ground level where it could absorb water. Consult a professional insulation installer to decide what type of insulation is best for you.

Available foam insulation materials include:

- Cementitious

- Phenolic

- Polyisocyanurate (polyiso)

- Polyurethane.

Some less common types include Icynene foam and Tripolymer foam. Icynene foam can be either sprayed or injected, which makes it the most versatile. It also has good resistance to both air and water intrusion. Tripolymer foam—a water-soluble foam—is injected into wall cavities. It has excellent resistance to fire and air intrusion.

Installation

Liquid foam insulation — combined with a foaming agent — can be applied using small spray containers or in larger quantities as a pressure-sprayed (foamed-in-place) product. Both types expand and harden as the mixture cures. They also conform to the shape of the cavity, filling and sealing it thoroughly. Slow-curing liquid foams are also available. These foams are designed to flow over obstructions before expanding and curing, and they are often used for empty wall cavities in existing buildings. There are also liquid foam materials that can be poured from a container.

Installation of most types of liquid foam insulation requires special equipment and certification and should be done by experienced installers. Following installation, an approved thermal barrier equal in fire resistance to half-inch gypsum board must cover all foam materials. Also, some building codes don’t recognize sprayed foam insulation as a vapor barrier, so installation might require an additional vapor retarder.

Costs

Foam insulation products and installation usually cost more than traditional batt insulation. However, foam insulation has higher R-values and forms an air barrier, which can eliminate some of the other costs and tasks associated with weatherizing a home, such as caulking, applying housewrap and vapor barrier, and taping joints. When building a new home, this type of insulation can also help reduce construction time and the number of specialized contractors, which saves money.

Structural Insulated Panels

Structural insulated panels (SIPs) are prefabricated insulated structural elements for use in building walls, ceilings, floors, and roofs. They provide superior and uniform insulation compared to more traditional construction methods (stud or “stick frame”), offering energy savings of 12% to 14%. When installed properly, SIPs also result in a more airtight dwelling, which makes a house quieter and more comfortable.

SIPs not only have high R-values but also high strength-to-weight ratios. A SIP typically consists of 4- to 8-inch-thick foam board insulation sandwiched between two sheets of oriented strand board (OSB) or other structural facing materials. Manufacturers can usually customize the exterior and interior sheathing materials to meet customer requirements. The facing is glued to the foam core, and the panel is then either pressed or placed in a vacuum to bond the sheathing and core together. SIPs can be produced in various sizes or dimensions. Some manufacturers make panels as large as 8 by 24 feet, which require a crane to erect.

The quality of SIP manufacturing is very important to the long life and performance of the product. The panels must be glued, pressed, and cured properly to ensure that they don’t delaminate. The panels also must have smooth surfaces and edges to prevent gaps from occurring when they’re connected at the job site. Before purchasing SIPs, ask manufacturers about their quality control and testing procedures and read and compare warranties carefully. SIPs are available with different insulating materials, usually polystyrene or polyisocyanurate foam.

Installation

SIPs are made in a factory and shipped to job sites. Builders then connect them together to construct a house. For an experienced builder, a SIPs home goes up much more quickly than other homes, which saves time and money without compromising quality. These savings can help offset the usually higher cost of SIPs.

Many SIP manufacturers also offer “panelized housing kits.” The builder need only assemble the pre-cut pieces, and additional openings for doors and windows can be cut with standard tools at the construction site.

When installed according to manufacturers’ recommendations, SIPs meet all building codes and pass the American Society for Testing and Materials (ASTM) standards of safety. In buildings constructed of SIPs, fire investigators have found that the panels held up well. For example, in one case a structure fire exceeded 1,000°F (538°C) in the ceiling areas and 200°F (93°C) near the floors, and most wall panels and much of the ceiling remained intact. An examination of the wall panels revealed that the foam core had neither melted nor delaminated from the skins. In similar cases, a lack of oxygen seemingly caused the fire to extinguish itself. The air supply in an airtight SIP home can be quickly consumed in a fire.

Areas of Concern

Fire safety is a concern, but when the interior of the SIP is covered with a fire-rated material, such as gypsum board, it protects the facing and foam long enough to give building occupants a chance to escape. As in any house, insects and rodents can be a problem. In a few cases, insects and rodents have tunneled throughout the SIPs, and some manufacturers have issued guidelines for preventing these problems, including:

Applying insecticides to the panels

Treating the ground with insecticides both before and after initial construction and backfilling

Maintaining indoor humidity levels below 50%

Locating outdoor plantings at least two feet (0.6 meters) away from the walls

Trimming any over-hanging tree limbs.

Boric acid-treated insulation panels are also available. These panels deter insects, but are relatively harmless to humans and pets.

Because it is so airtight, a well-built SIP structure requires controlled fresh-air ventilation for safety, health, and performance, and to meet many building codes. A well-designed, installed, and properly operated mechanical ventilation system can also help prevent indoor moisture problems, which is important for achieving the energy-saving benefits of an SIP structure.

To know more about Insulation materials check here !