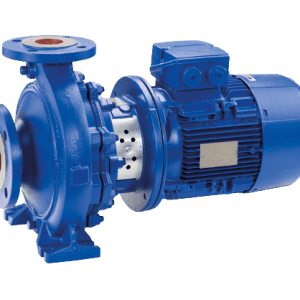

MCPK

| Technical Data | |

| Max. flow rate | 1160 m3/h |

| Max. head | 162 m |

| Max. allowed working pressure | 25 bar |

| Max. allowed fluid temperature | 400 °C |

Submit the inquiry to get direct support from our product team

Horizontal, end suction, centrifugal, radially split, volute casing process pumpin black pull-out design, fitted with a radial impeller.

Able to handle aggressive, organic and inorganic fluids in chemical and process industries like paper, cellulose, sugar, food, textile, drugs, breweries, pharmaceuticals and distilleries.

Main Applications

-

Pump for handling aggressive liquids in the chemical and petrochemical industries

-

Pulp and paper industry

-

Seawater desalination/reverse osmosis

-

Food industry and beverage industry

-

Fossil-fuelled power stations

-

Chemical industry

-

Petrochemical industry

-

Refineries

-

Sugar industry

-

Alcohol industry

Benefits

-

Hydraulic characteristics optimized for excellent efficiency and NPSH, ensuring energy-efficient and environmentally friendly use of resources

-

Lower investment costs as duty points required can be achieved with smaller pump sizes

-

Lower operating costs due to reduced energy consumption, optimized spare parts concept, and hard-wearing, service-friendly design

-

Flexible use due to modular design regarding hydraulic system materials, sealing elements, bearing brackets, coupling, baseplate and drive

User Reviews

Be the first to review “MCPK”

No more offers for this product!

General Inquiries

There are no inquiries yet.

There are no reviews yet.