CI029 Cast Iron Butterfly Valve PN-16 (Wafer Type)

- Item Code: CI0029

- Disc: Ductile Iron

- Pressure Rating: PN-16

- Testing Standard: BSEN 12266 Part-1

- Size Range: 40mm to 400mm

- Product Standard: BS 5155, EN 593, API 609 CAT.A.

Suitable For

Submit the inquiry to get direct support from our product team

Material Specification

CI029 Cast Iron Butterfly Valve PN-16

| P. NO. | NAME OF PART | MATERIAL | ||

|---|---|---|---|---|

| 1 | LEVER | 1-1/2″ TO 6″ | M.S. SHEET (IS 2062) / C.C.S. (ASTM A216 Gr. WCB) / NODULAR IRON (B.S. 2789 Gr. 500/7) |

|

| 8″ TO 12″ | ||||

| 2 | SPRING WASHER | CARBON STEEL | ||

| 3 | COVER PLATE | M.S. SHEET | ||

| 4 | NUTS | C.S. (BS 4190) / ALLOY STEEL (ASTM A194 Gr.2H) | ||

| 5 | BOLTS | C.S. (BS 4190) / ALLOY STEEL (ASTM A193 Gr.B7) | ||

| 6 | BODY | C.I. (EN 1561 Gr. GJL 200) | ||

| 7 | UPPER STEM | S.S. (ASTM A276 TYPE 410) OR ITS EQ. | ||

| 8 | ‘O’ RING | BUNA-N / EPDM (SHORE HARDNESS 60° ±4) | ||

| 9 | MOULDED LINER | BUNA-N / EPDM (SHORE HARDNESS 70° ±4) | ||

| 10 | LOWER STEM | S.S. (ASTM A276 TYPE 410) OR ITS EQ. | ||

| 11 | BUSHING | HEAVY DUTY CORROSION RESISTANT TO ABSORB SIDE THRUST | ||

| 12 | WASHER | BUNA-N / EPDM (SHORE HARDNESS 60° ±4) | ||

| 13 | GRUB SCREW | MILD STEEL | ||

| 14 | DISC | D.I. (ASTM A395) | ||

| 15 | BUSH | PH. BRONZE / PTFE | ||

| 16 | TAPER PIN | STEEL (HARDENED) | ||

| 17 | GEAR BOX | C.I. (EN 1561 Gr. GJL 200) | ||

| 18 | HAND WHEEL | C.I. (EN 1561 Gr. GJL 200) / M.S. (IS 2062 Gr.B) | ||

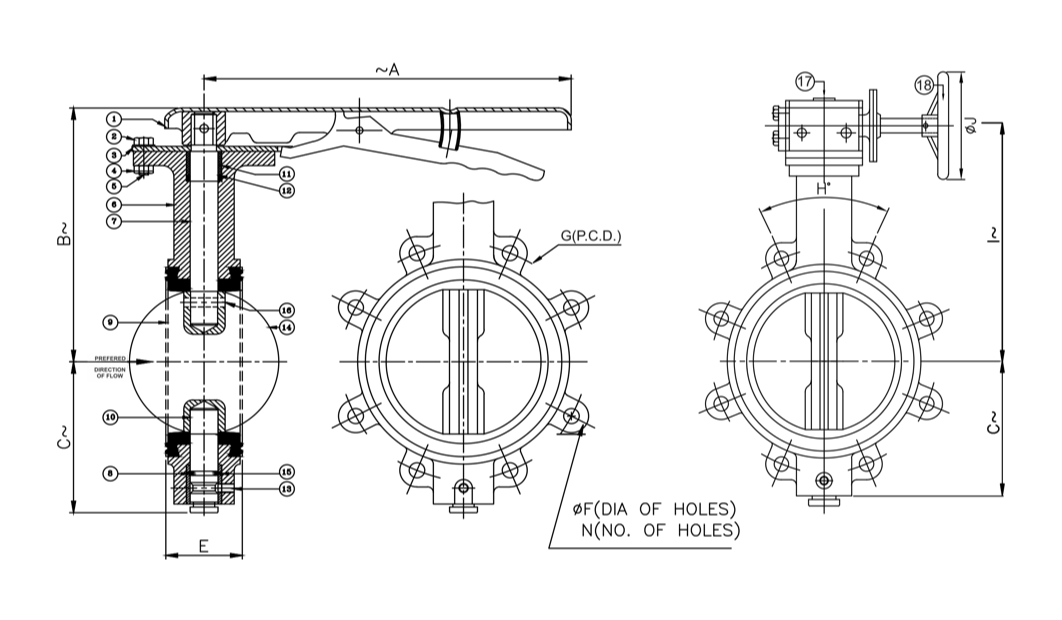

Dimensional Data

| SIZE (mm) | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ~A | 260 | 260 | 260 | 260 | 260 | 260 | 260 | 356 | 406 | 406 | – | – |

| B~ | 120 | 133 | 150 | 153 | 210 | 200 | 237 | 235 | 290 | 330 | – | – |

| C~ | 64 | 75 | 96 | 100 | 120 | 140 | 147 | 178 | 214 | 260 | 281 | 315 |

| E | 33±1 | 43±1 | 46±1 | 46±1 | 52±1 | 56±1 | 56±1 | 60±2 | 68±2 | 78±2 | 92±2 | 102±2 |

| ∅F | 15.8 | 19 | 19 | 19 | 19 | 22.3 | 22.3 | 22.3 | 25.4 | 25.4 | 28.6 | 28.6 |

| G | 98.5 | 120.6 | 139.7 | 152.4 | 190.5 | 215.9 | 241.3 | 298.4 | 361.9 | 431.8 | 476.2 | 539.8 |

| I~ | – | – | – | – | – | – | 240 | 240 | 290 | 330 | 340 | 412 |

| ∅J | – | – | – | – | – | – | 200 | 200 | 250 | 250 | 300 | 500 |

| N | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 12 |

Principle Features

INTRODUCTION

Leader Butterfly Valves are designed to meet the flow control requirement of plumbing, fire-fighting and HVAC application. The body seat is vulcanised in-situ onto the body and offers 100% bi-directional sealing. The lugged wafer-style body has universal design to fit between flanges of all almost all standards.

- Design Standard: BS 5155, EN 593, API 609 CAT. A.

- Lugged Wafer type design makes it compact and takes lesser space.

- Dynamic sealing of concentric disc is obtained with vulcanised rubber seat at very low torque.

- High-precision disc external profile for smooth operation & tight shut-off sealing with low operating torque.

- Moulded rubber body seat extending on to the contact faces ensures perfect sealing and eliminates the need for separate flange gaskets.

- Notch plate ensures the locking of the hand lever at different positions in addition to open and closed positions.

- Shaft sealing is ensured by double sealing of Bush and ’0’ ring combination.

- Body castings made of superior FG 260 grade cast iron to ensure additional strength.

- Valve disc made of ductile iron with epoxy coating offers high strength against pressure.

- Shaft made of martensitic stainless steel to ensure maximum strength and torsional rigidity.

- Two-piece stem design which is precisely guided between the PTFE bush & Rubber ‘0’ Rings to prevent leakage, corrosion, and stem seizure.

- Taper disc holder pins to ensure shockproof shaft to disc connection & suitability of replacement at field.

- Easy visual control of open/closed position marked on the notch plate.

- Operation mode manual, gear, electric, pneumatic.

- Available with locking arrangement on request.

- Temper Switch / supervisory limit switches option available on request.

- Top flange as per ISO 5211 to suit F Series flanges of Gears and Actuators.

END CONNECTION

- Suitable for Clamping between flanges as per ASME B16.1 Class-125, ASME B16.5 Class-150, IS 6392, Table 17, IS 1538, BSEN 1092 PN25, BS:10 Table D, E, F, H.

UTILISATION & SERVICE

- Best suited for water, HVAC, fire-fighting, compressed air & oil service.

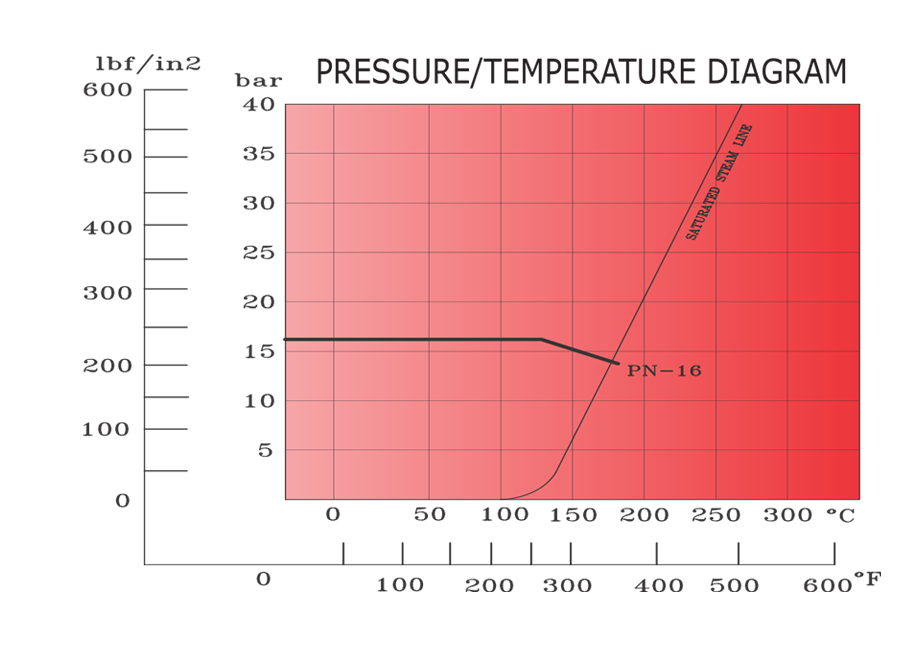

WORKING PRESSURE & TEMPERATURE LIMITS

- Maximum Working Pressure: 16 Bar.

- Maximum Working Temperature: 120°C.

- See Pressure / Temperature Diagram.

TEST PRESSURE (Hydrostatic)

| Rating | PN-16 |

|---|---|

| Body (Hyd.) | 24 Bar |

| Seat (Hyd.) | 17.6 Bar |

There are no reviews yet.