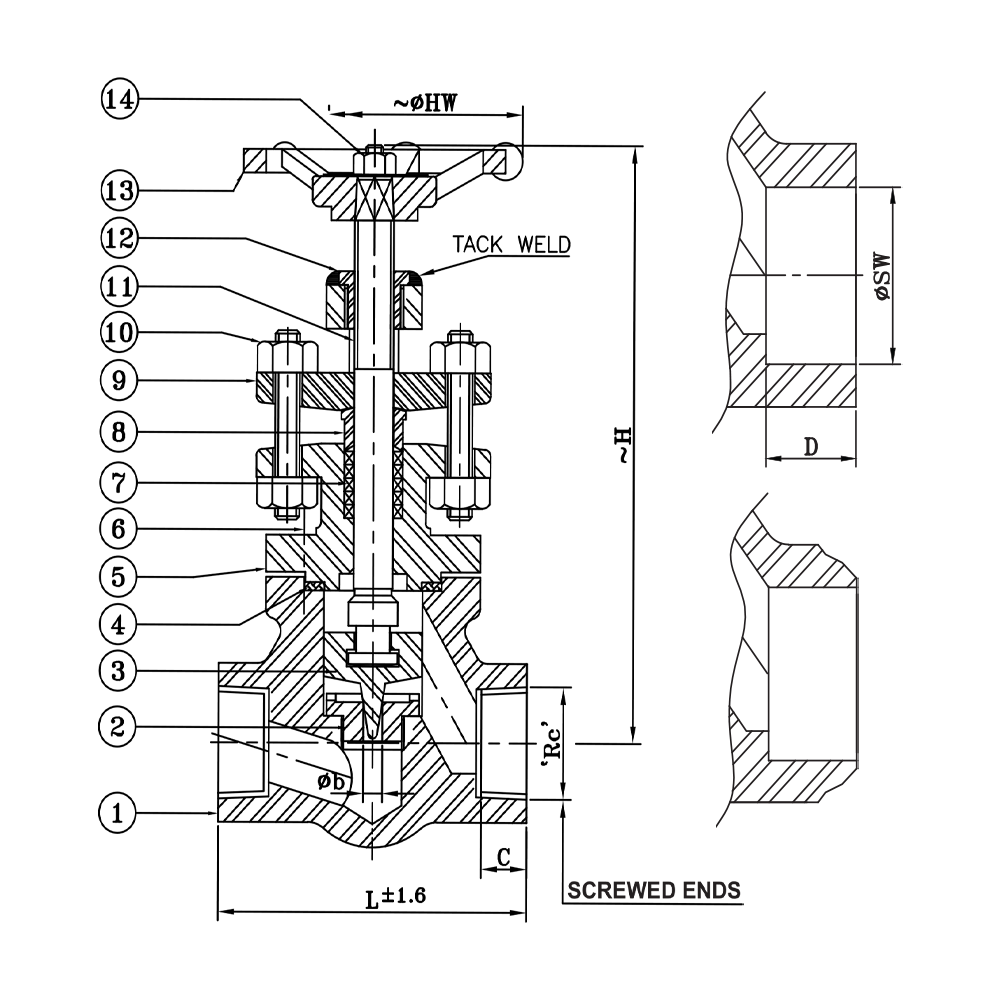

FCS019 Forged Steel Needle Valve (Socket Weld)

- Item Code: FCS019

- Pressure Rating: CL-800

- Testing Standard: API-598, BSEN 12266 Part-1

- Size Range: 15mm to 50mm

- Product Standard: API 602, BSEN ISO 15761

Suitable For

Submit the inquiry to get direct support from our product team

Material Specification

FCS019 Forged Steel Needle Valve (Socket Weld)

| S. No. | PART NAME | CARBON STEEL | ALLOY STEEL | STAINLESS STEEL | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | BODY | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 2 | SEAT RING | ASTM A276 TYPE 410 | SS 304 | SS 410 | SS 410 | SS 410 | SS 410 | SS 304 | SS 316 | SS 304L | SS 316L |

| 3 | DISC | ASTM A217 Gr. CA15 / ASTIM 276 TYPE 410 | SS 304 | CA15 / SS410 | CA15 / SS410 | CA15 / SS410 | CA15 / SS410 | SS 304 | SS 316 | SS 304L | SS 316L |

| 4 | GASKET | SPIRAL WOUND STAINLESS STEEL GRAPHOIL FILLER | |||||||||

| 5 | BONNET | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 6 | STUDS | A193 B7 | A320 L7 | A193 B7 | A193 B7 | A193 B16 | A193 B16 | A193 B8 | A193 B8 | A193 B8 | A193 B8 |

| 7 | PACKING | FLEXIBLE GRAPHITE | |||||||||

| 8 | GLAND | A182 F6a | SS 304 | A182 F6a | A182 F6a | A182 F6a | A182 F6a | SS 304 | SS 316 | SS 304L | SS 316L |

| 9 | GLAND FLANGE | A105 | A350 LF2 | A182 F5 | A182 F11 | A182 F22 | A182 F9 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 10 | NUTS | A194 2H | A194 Gr.4 | A194 2H | A194 Gr.4 | A194 Gr.4 | A194 Gr.4 | A194 Gr.8 | A194 Gr.8 | A194 Gr.8 | A194 Gr.8 |

| 11 | STEM | ASTM A276 TYPE 410 | SS 304 | SS 410 | SS 410 | SS 410 | SS 410 | SS 304 | SS 316 | SS 304L | SS 316L |

| 12 | YOKE SLEEVE | ASTM A582 TYPE 416 | |||||||||

| 13 | HAND WHEEL | DI.A536 Gr. 80-55-06 | |||||||||

| 14 | HAND WHEEL RETAINING NUT | STEEL | |||||||||

Dimensional Data

| SIZE (mm) | 15 | 20 | 25 | 32 | 40 | 50 | |

|---|---|---|---|---|---|---|---|

| L | 80 | 88 | 100 | 124 | 145 | 170 | |

| ∅b | 5 | 6.5 | 8.5 | 12 | 15 | 18.5 | |

| ~∅HW | 82 | 90 | 96 | 114 | 155 | 155 | |

| ~H | 140 | 155 | 172 | 198 | 235 | 270 | |

| C | 17 | 18 | 21 | 21 | 23 | 24 | |

| Rc | 1/2″ | 3/4″ | 1″ | 1-1/4″ | 1-1/2″ | 2″ | |

| ∅SW | AS PER ASME B16.11 | 22.2 | 27.6 | 34.3 | 43.1 | 49.2 | 61.7 |

| 21.8 | 27.2 | 33.9 | 42.7 | 48.8 | 61.2 | ||

| D | 11 | 14 | 14 | 14 | 14 | 17 | |

Principle Features

INTRODUCTION

Leader forged steel Needle (Regulating) valve offers renewable seat by default with rising stem and hand wheel. It blocks the flow of pipeline through the rotation and lifting of hand wheel as well as stem to drive the lift of disc. There is no relative friction between disc and body sealing surface. The Needle (Regulating) valves have the feature of long service life for opening and closing, can be used as a shut-off valve for small-size pipelines.

- Design Std.: API 602/ BSEN ISO 15761

- Pressure Temperature Rating as per ASME B16.34, BSEN ISO 15761

- Sturdy design for high-pressure & temperature service

- Bolted body-bonnet design, Valves with welded bonnet also available on request.

- Bolted body-bonnet joints provided with spiral-wound stainless steel gasket and graphite filler for protection against leaks.

- Die-formed graphite inner packing rings and braided graphite end rings with Inconel wire reinforcement and corrosion inhibitor.

- Tapered shoulder on the stem for back seating.

- Self-aligning type gland assembly with stud-and-nut tightening

- Socket welded ends as per ASME B16.11

- Screwed Female Taper ends as per ASME B1.20.1 (NPT) / BS 21 & Screwed Female Parallel ends as per ISO 228 / BS 21 available on request.

- Butt weld ends as per ASME B16.25 available on request.

- Valves can be offered with electrical actuators on request.

- Low-Temperature Carbon Steel & Austenitic SS forging for body and bonnet with extended bonnet design qualified as per BS 6364 for Cryogenic service available on request.

- Valves can be offered to NACE MR-0175 and other special NACE requirements.

- Valves are available with IBR certification.

- Low Emission, FET-qualified valves as per API 624 / ISO 115848-1 can be offered with API 622 (FET), API 607 (Fire Safe) qualified gland packing.

TEST PRESSURE(Hydrostatic)

| Rating | CL-800 |

|---|---|

| Body (Hyd.) | 207 Bar |

| Seat (Hyd.) | 152 Bar |

| Seat (Air) | 6.9 Bar |

END CONNECTION:

- Socket Weld / Screwed ends / Butt Welded ends.

WORKING PRESSURE:

- Maximum working pressure 138 Bar.

TEMPERATURE LIMITS:

- Maximum working temperature 425°C.

TRIM MATERIAL COMBINATION (ON REQUEST)

| Trim No. | Seat Ring Face | Wedge Seat Face | Stem | Backseat Bush | Lantern Ring |

|---|---|---|---|---|---|

| 2 | F304 | F304 | F304/AISI304 | F304/AISI304 | F304/AISI304 |

| 5 | STELLITE(#6) | STELLITE(#6) | F6a/AISI410 | F6a/AISI410 | F6a/AISI410 |

| 8 | STELLITE(#6) | F6a/13%Cr. | F6a/AISI410 | F6a/AISI410 | F6a/AISI410 |

| 9 | MONEL | MONEL | MONEL | MONEL | MONEL |

| 10 | F316 | F316 | F316/AISI316 | F316/AISI316 | F316/AISI316 |

| 12 | 316+Stellite(#6) | 316 | F316/AISI316 | F316/AISI316 | F316/AISI316 |

| 13 | ALLOY 20 | ALLOY 20 | ALLOY 20 | ALLOY 20 | ALLOY 20 |

User Reviews

Be the first to review “FCS019 Forged Steel Needle Valve (Socket Weld)”

General Inquiries

There are no inquiries yet.

There are no reviews yet.